Contact Us

Category: Spark Arrestor

Contact Us

Quantity: In Stock

Selected variant:

Selected variant:

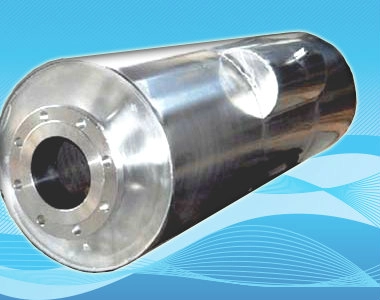

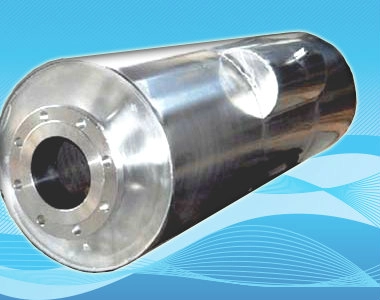

.png) ISTIQ Spark Arrester

ISTIQ Spark Arrester

Eliminate Noise and Hazards

In a world where the roar of diesel generators disrupts the peace of our workspaces and communities, the quest for quiet has never been more critical. It is a solution that silences the clamor and safeguards your environment from hazardous sparks and emissions. ISTIQ Spark Arrester, a groundbreaking innovation designed specifically for Diesel Generator Sets, is poised to eliminate hazards and noise at the same time.

Revolutionary Design, Unmatched Performance

ISTIQ Spark Arrester is not just any noise control solution. It's a testament to engineering excellence and a commitment to environmental stewardship. Here's why:

.png) Models:

Models:

.png) Features: Features: |

| • Heavy gauge, hot rolled, cold quenched sheet steel • Flanges (Table C or ANSI) • Threaded ends (BSP or SI) • Drain Plugs • Heat-resistant aluminum paint |

.png) Applications: Applications: |

| • Diesel Engines • Blowers • Vacuum Pumps • Compressors |

Engineering Simulation

At ISTIQ, we've harnessed advanced simulation software's power to redefine noise level and pressure drop calculation precision. Our engineers, seasoned through years of dedicated practice, have mastered the intricacies of this technology, enabling us to offer you predictions and guarantees. The confidence in our calculations means you can sidestep the costly and time-consuming cycle of trial and error. Partner with ISTIQ and embrace the assurance of cost-effective, expertly validated solutions that stand to revolutionize your project outcomes.

Take Action for a Quieter and Safer Tomorrow

Embrace the future of noise control and environmental protection with ISTIQ Spark Arrester. Whether you're looking to enhance workplace productivity, protect sensitive environments, or enjoy the sound of silence, ISTIQ is your partner in making it happen.

Don't let noise dictate your life. Contact us today via email or WhatsApp to discover how the ISTIQ Spark Arrester can eliminate noise and hazards. Experience the difference, improve performance, and enjoy a safer environment. The time to act is now—upgrade your equipment and embrace a quieter, safer tomorrow with ISTIQ.

For more information:

CALL US NOW for inquiry at +603-7846 5188/+603-7846 5288 (Office) or

011-2772 0340 (Whatsapp) or

email at noisecontrol.istiq@gmail.com

Specifications

We specialize in industrial noise control, oil & gas industry noise control, architectural acoustics, traffic noise control and audiometric test room.

1, Jalan Utarid U5/17, Seksyen U5, Mahsing Integrated Industrial Park, 40150 Shah Alam, Selangor, Malaysia.

© 2015-2024 ISTIQ Noise Control Sdn Bhd 199501013082 (342283-V)

Visitor :

Powered by NEWPAGES